Frigoblock's Growth Journey in Global Markets: Export Strategies and 2026 Vision

Interview: Cemal Yılmaz – Chairman of the Board of Frigoblock

1. Could you tell us about your company's export journey? Which countries do you export to, and what are the reasons why your products are preferred in the international market?

Our export journey at Frigoblock began in the early 2000s with strategic steps taken by analyzing regional market needs. Initially starting with shipments to nearby regions, this process gradually evolved into a systematic market entry strategy.

Today, we have a broad and dynamic export network stretching from the Middle East to North Africa, from Europe to Central Asia, and from the Balkans to South America. We export our products particularly to countries with which we have regular business volumes, such as Georgia, the United Kingdom, Morocco, Greece, Russia, Uzbekistan, Turkmenistan, Azerbaijan, Chile, and Colombia.

Our fundamental strategy in expanding into these markets is based on developing customized solutions for each customer by analyzing the climatic conditions, energy costs, technical regulations, and expectations of the refrigeration industry in each region. Establishing local partnership models, providing technical support during project planning processes, and being able to adapt our product range to meet specific needs are the factors that set us apart in the global market.

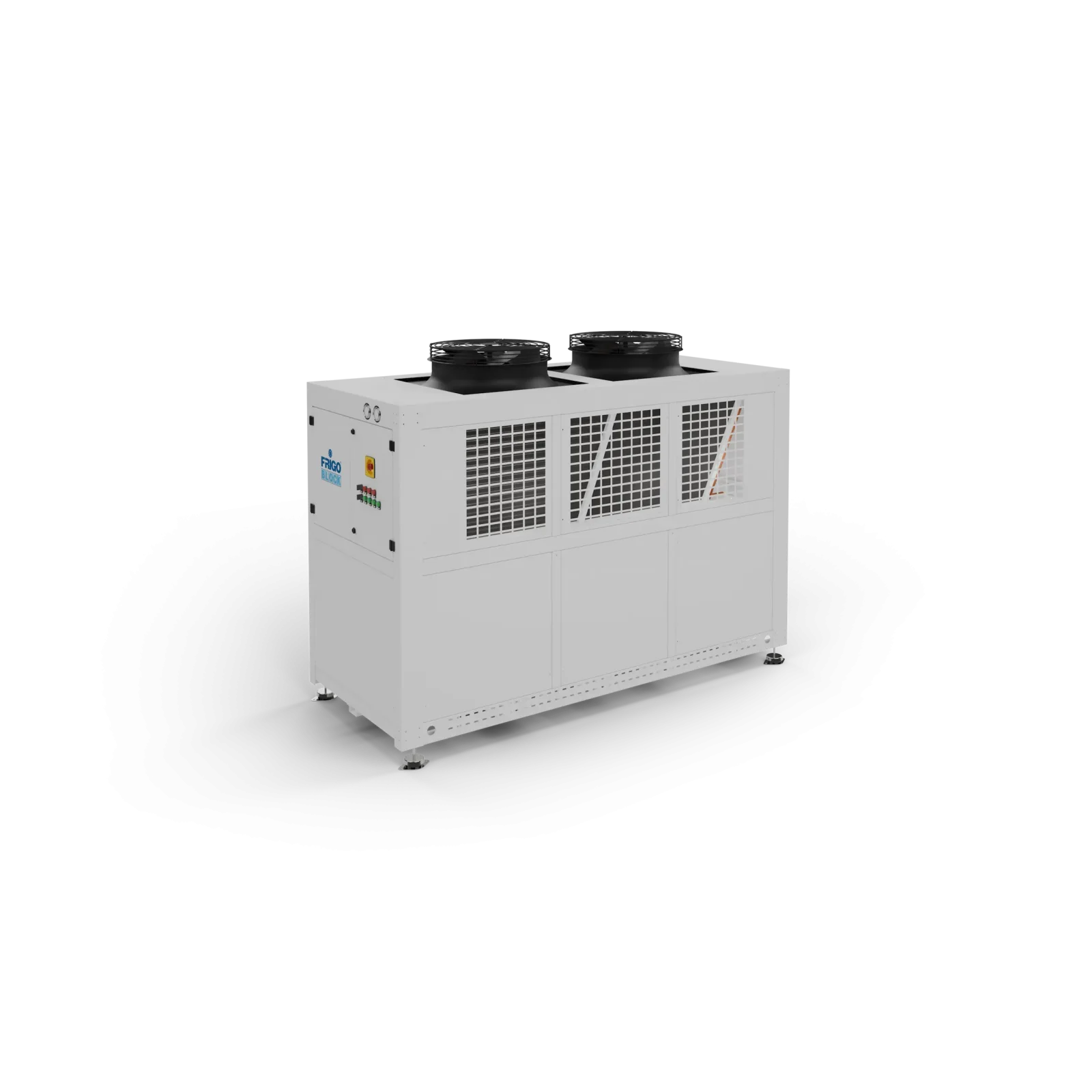

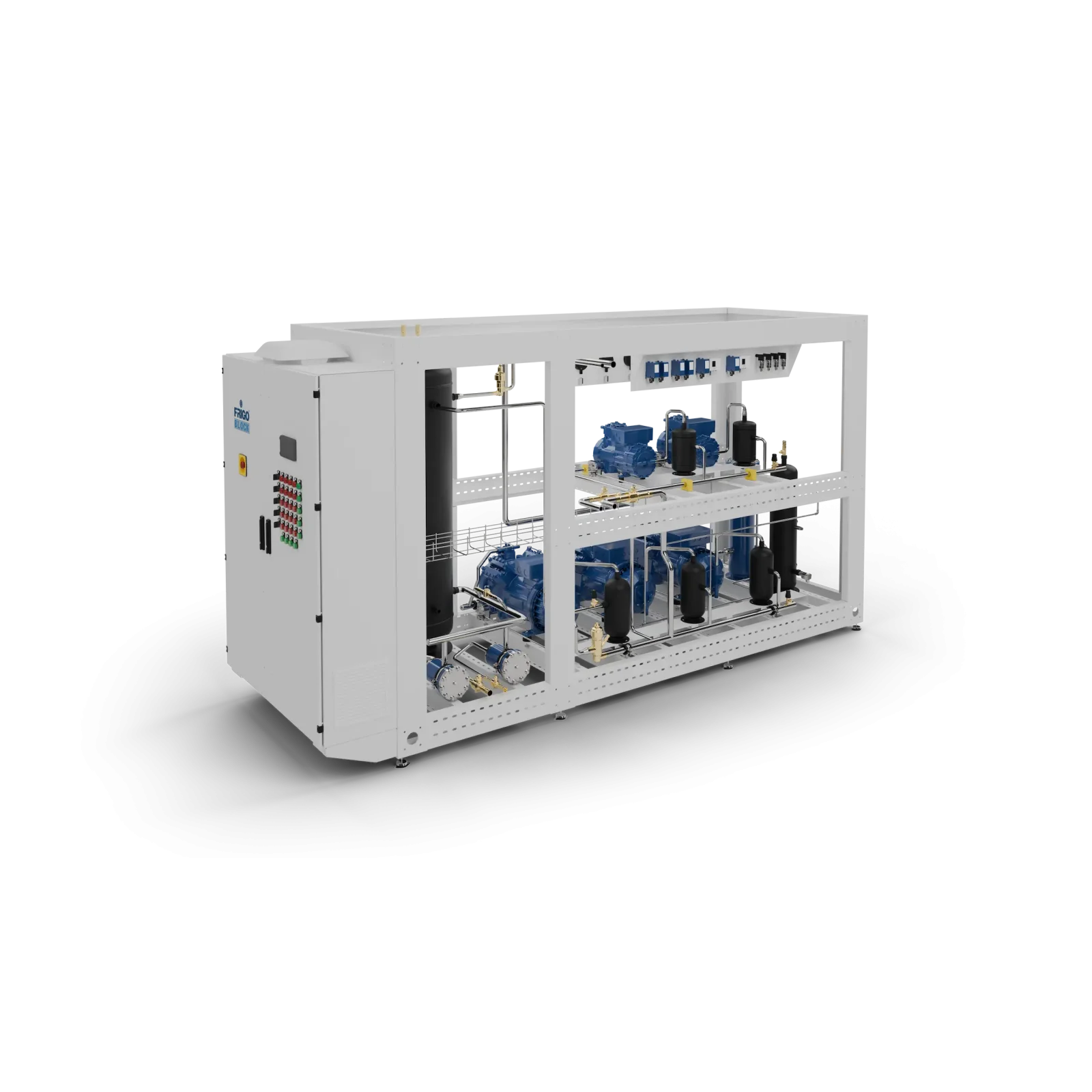

Frigoblock's popularity in the international market is primarily due to our custom design and production capabilities, our flexibility in working with different refrigerants, our energy-efficient system infrastructure, and our high reliability standards.

2. What are the main challenges you face in your export activities, and what strategies do you employ to overcome them?

In our export operations, we face various challenges such as fluctuations in the global supply chain, increases in logistics costs, differences in technical regulations, and competitive pressure from local firms. Delays in the international supply of critical components, in particular, make planning even more delicate.

To overcome these challenges, we are developing flexible, fast, and alternative models in production planning. By implementing a strategy of working with different suppliers for critical components, we minimize risks; at the same time, we develop customized product variants that meet the technical specifications of each market.

We are expanding our after-sales service network and increasing the continuity of our technical service. In the coming period, strengthening regional service partnerships and establishing a structure that provides on-site engineering support in high-volume markets are among our primary goals.

3. What flexibility do you offer in production and product design to adapt to the demands of green energy and digitalization in global markets?

Energy efficiency, the use of low GWP refrigerants, reduced carbon footprint, and remote system monitoring have become critical expectations in global markets. At Frigoblock, we closely follow these trends and integrate technology into our product development processes.

We design systems that operate with ammonia (NH₃), CO₂, and next-generation low-GWP refrigerants; developing environmentally friendly solutions that reduce operating costs. We have a strong engineering infrastructure that can tailor products to project-based requirements.

As part of our digitalization efforts, we are developing control systems and user-friendly automation interfaces that enable real-time monitoring of equipment performance. This transforms our products from mere cooling devices into intelligent systems that increase operational efficiency.

4. How would you assess Türkiye's global competitiveness in the industrial refrigeration sector?

Turkey holds a strong position in the international market thanks to its engineering culture, production speed, project adaptation capabilities, and cost advantage. Turkish companies particularly stand out with their high adaptability in industrial systems requiring project-based and customized designs.

A strong supporting industry infrastructure, high-quality technical personnel, and a fast production culture make Turkish manufacturers more competitive. At Frigoblock, we leverage these advantages and position our brand as a reliable, fast, and technically strong solution partner worldwide.

5. How do you evaluate the year 2025 in terms of exports? What are your new market targets for 2026?

Despite global economic fluctuations, we expect 2025 to close with export volumes slightly above last year's levels. Increased industrial food processing investments in the Gulf countries and the rapidly growing cold chain infrastructure in Africa present significant opportunities.

Our primary goals for 2026 include strengthening our position in the US market and consolidating our distributor network in Western Europe and Northwest Africa. We also aim to increase our brand's global visibility by expanding our participation in international trade fairs.

Digital promotional activities and the trade delegation activities of the Air Conditioning Industry Exporters Association also hold an important place in our 2026 plans.

6. What are the most important pieces of advice you would give to companies that are about to start exporting?

For companies wishing to start exporting, the most critical point is accurately analyzing the real needs of the target market. Correctly interpreting technical standards, clearly defining customer expectations, and conducting meticulous market research shorten the path to success.

Establishing long-term and reliable local partnerships is a cornerstone of a sustainable export structure. Quality reliability, adherence to delivery times, and a strong after-sales service approach enhance the brand's long-term desirability.

We advise companies to focus on building sustainable brand value and increasing their international visibility through digital communication tools, rather than short-term gains.